Copper & Aluminium Busbars & Profiles

At PROTECH INDIA, we specialize in custom-manufactured copper and aluminium busbars engineered to match customer-specific drawings, electrical performance needs, and mechanical specifications. Our busbar solutions are designed for high-current power distribution systems, switchgear, EV power modules, renewable energy panels, transformers, and industrial control panels, ensuring precision, conductivity, and long-term reliability.

High-Purity Copper Busbars with Electrical-Grade Performance

We manufacture copper busbars with 99.97% purity and superior electrical conductivity, using premium Electrolytic Tough Pitch (ETP) and Oxygen Free Copper (OFC) materials.

Our production capabilities include:

- Thickness: 0.5 mm to 20.0 mm

- Width: 5.0 mm to 200.0 mm

- Precision plating: Tin, Nickel & Silver (3–30 microns)

- Full statutory test reports for conductivity, coating thickness, hardness & structural integrity

These long-life, corrosion-resistant busbars are widely used in power electronics, battery storage, power distribution boards, UPS systems, and high-current electrical equipment.

Advanced Aluminium Busbars for Lightweight Electrical Applications

Our custom aluminium busbars offer lightweight performance with optimal current-carrying capabilities, making them ideal for EV battery packs, solar combiner boxes, HVAC control units, panel boards, and railway electrical systems.

We deliver:

- Precision bending

- Clean edge finishing

- Profile machining

- Prototype-ready builds

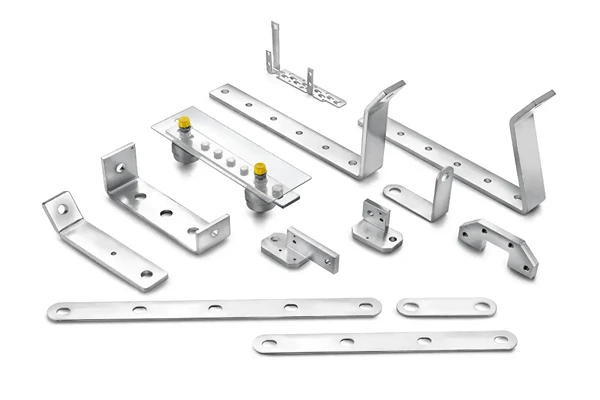

Complex Profile Bending for Copper & Aluminium Busbars

PROTECH INDIA is one of the few manufacturers capable of producing complex 3D busbar bends and multi-plane copper/aluminium busbar profiles with extreme accuracy.

Our CNC-controlled systems support:

- Vertical & Horizontal Bending

- U-Bending & L-Bending

- Twisting & Offset Bending

- Custom multi-profile shaping

We also offer quick-turn prototype development to support new product launches and R&D requirements.

Extruded Copper & Aluminium Profiles with In-House CNC Machining

We manufacture precision-extruded busbar profiles and machine them in-house using CNC machining centres, helping customers achieve:

- Significant raw material cost savings

- Reduced machining hours

- Lower scrap generation

- Enhanced dimensional stability

All extruded profiles can be Tin / Nickel / Silver plated (3–30 microns) as per specifications, supported with certified test reports.

Full Range of Manufactured Components

Along with custom busbars, PROTECH INDIA also manufactures:

- Press Components

- Copper & Aluminium Busbar Assemblies

- Sheet Metal Cabinets & Enclosures

- Hinges, Latches & Industrial Handles

- Aluminium Heatsinks & Extruded Profiles

- Copper Shunts & Laminated Assemblies

- Prototype Components for R&D & New Product Development